RESEARCH

Laboratory Overview

Our laboratory is engaged in research and development of new technologies that leverage the characteristics of being compact, lightweight, energy-efficient, and environmentally friendly through the development of small robots and small actuators.

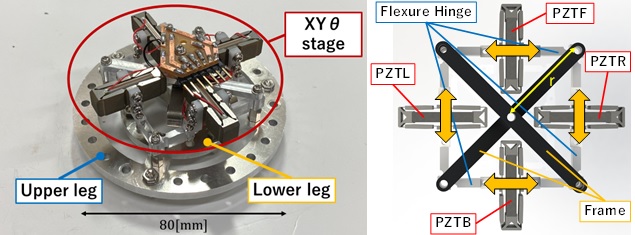

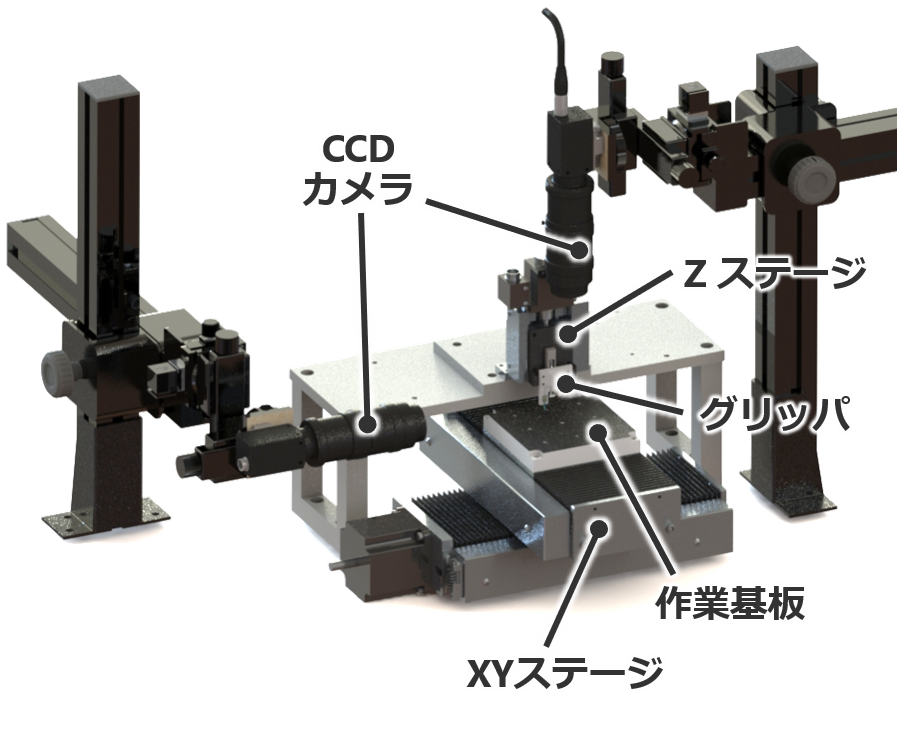

Currently, we are conducting research on the mechanism development of holonomic mobile robots, precise XYθ displacement measurement using encoders, automatic robot control via machine learning, precision manipulation in liquids using grippers based on liquid bridge forces and vibration pipettes, and various actuators such as SMA (Shape Memory Alloy) and piezoelectric actuators.

Holonomic Mobile Robot

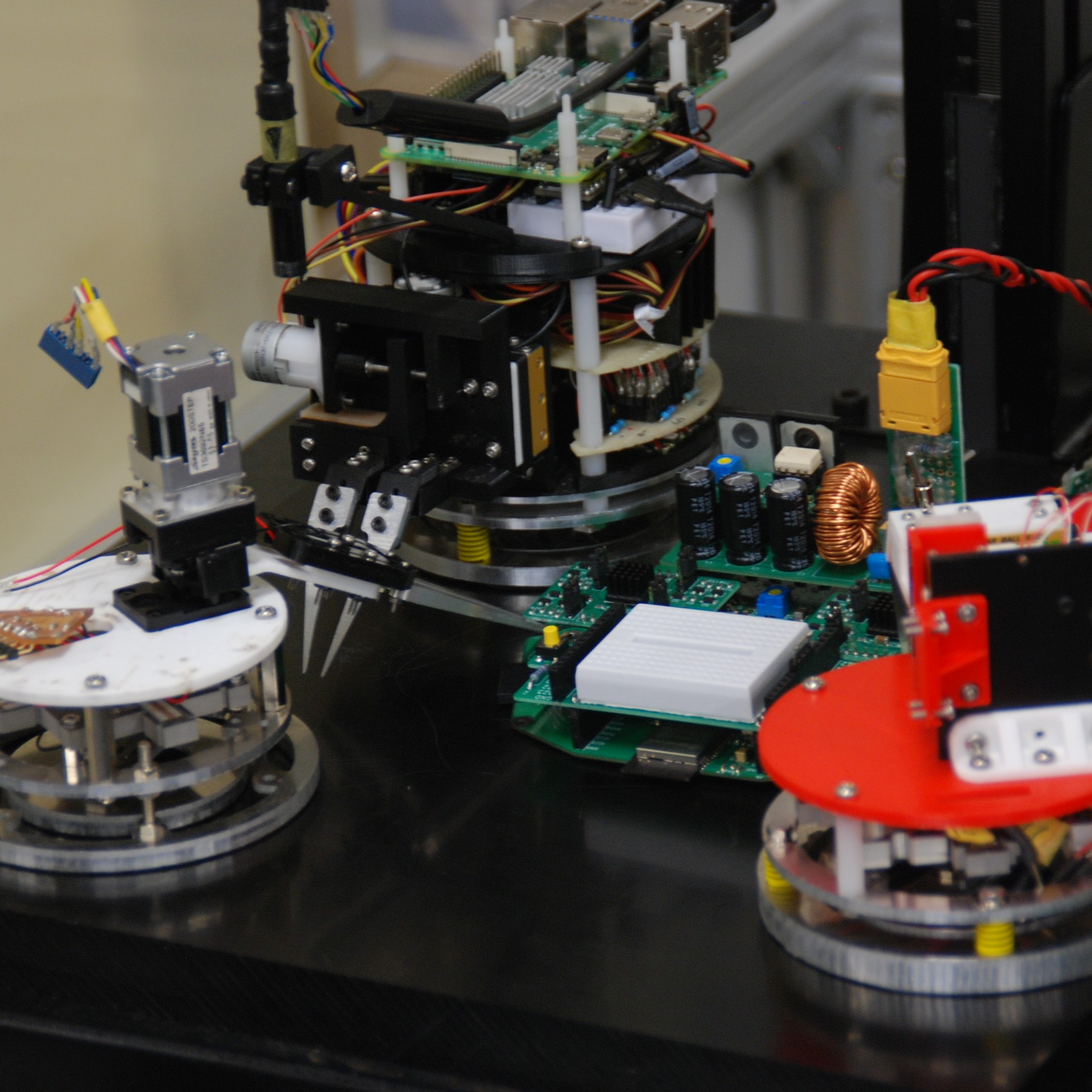

We are also conducting research on coordinated precision tasks using multiple small mobile mechanisms. So far, we have developed a wide-area guidance method with formation control functionality using swarm control technology.

By coordinating the work of numerous robots, we aim to create an ultra-lightweight robot factory that features energy efficiency, low vibration, minimal floor space, and independent three-degree-of-freedom path generation.

Additionally, We are conducting research on cooperative precision work using multiple small self-propelled mechanisms with a single function. We have developed a wide-area guidance method with formation control function for multiple units using swarm control technology.

By working together, we aim to realize a ultra-lightweight robot factory that features energy saving, low vibration, low floor space, and independent three-degree-of-freedom path generation.

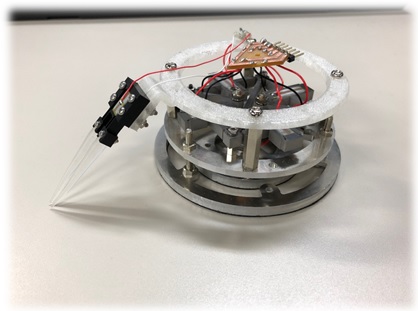

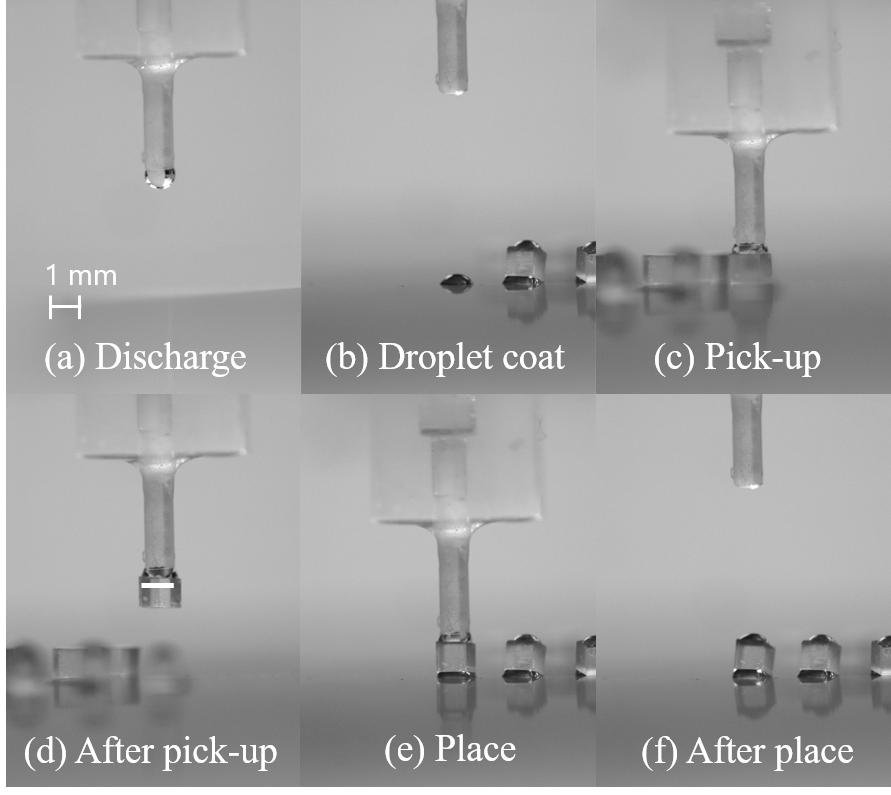

Capillary force Gripper

Our laboratory is developing manipulation devices that use liquid bridging force, which is a departure from conventional object manipulation techniques. Liquid bridging force is an adhesion force generated by the surface tension of water and Laplace pressure. At the microscale, adhesion forces such as electrostatic forces are more dominant than gravity due to the scale effect. Therefore, when manipulating microscopic parts with an air nozzle or tweezers, this adhesion force causes them to stick to the tip of the nozzle. Liquid cross-linking forces are more dominant than adhesion forces and are therefore suitable for manipulating micro-parts.

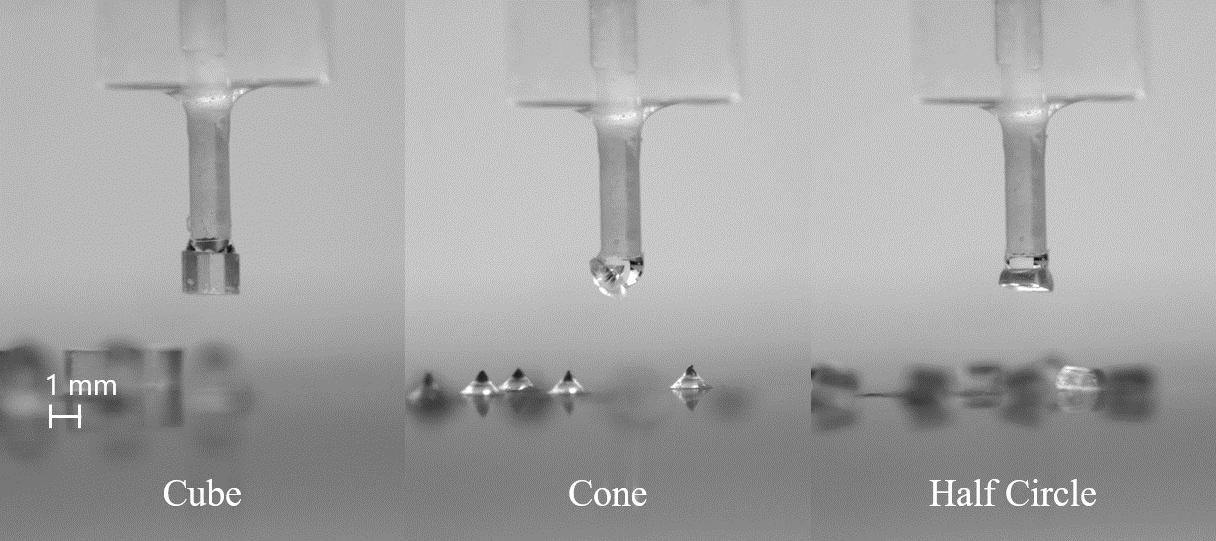

Liquid bridging force has not only the advantage of force due to the scale effect, but also has the advantage of adhesion of liquid along the surface of the object to be operated, which is less affected by the surface shape and less likely to damage the object. We have developed a mechanism that continuously supplies liquid to the gripper tip using capillary action. This mechanism has successfully picked up parts of various shapes such as cubes, triangular pyramids, and semi-cylinders.

Multi-axial non-contact in situ micromanipulation by steady streaming around two oscillating cylinders on holonomic miniature robots

In the field of micromanipulation, an in situ three-axial rotation of a microscale object remains difficult to realize, with rotational resolution and repeatability remaining low. In this research, we describe the fundamental principle, properties, and experimental results of multi-axial non-contact in situ micromanipulation of an egg cell driven by steady streaming generated around an oscillating cylinder. A continuously oscillating cylinder generates the steady streaming that draws heterogeneous miniscule objects toward the cylinder. If it is trapped by an eddy near the tip of the cylinder, it continuously rotates around the vertical axis at a fixed point. If it is trapped by a swirl flow generated around the side of the cylinder, it rotates around the horizontal axis. We demonstrate that the conditions of the vertical and horizontal rotations are determined by two dimensionless numbers: Re and a/rc.

In our experiments, we obtained rotational resolutions of 0.05° and 0.11° and maximal angular velocities of 34.8°/s and 188°/s for the vertical and horizontal rotations for mouse egg cell, respectively.

We also developed unique micromanipulation methods using two oscillating pipettes attached to holonomic miniature robots. We successfully manipulated five degrees of freedom of the cell with the steady streaming. It can be applied in microfluidics, biomedical, and heterogeneous microassembly applications.